Our liquid nitrogen system offers two types of vacuum insulation, which can be customized according to your specific requirements:

Static vacuum: Static vacuum insulation, the vacuum annular space has been evacuated and sealed in the factory. Static vacuum insulation design is used to maintain a consistent vacuum level throughout the entire service life of the liquid nitrogen system. Providing excellent insulation for your system means that once a vacuum is formed and sealed, there is no need for further extraction or on-site maintenance.

Dynamic vacuum: Dynamic vacuum insulation, we provide continuous on-site extraction process through vacuum pumps. This type of insulation ensures that the vacuum annulus space remains at the optimal level throughout the entire system operation. Dynamic vacuum insulation has the advantage of strong adaptability, and the vacuum degree of the liquid nitrogen system can be adjusted according to your specific requirements or changes in operating conditions.

Understanding the differences between static and dynamic vacuum insulation is crucial for selecting the most suitable solution for liquid nitrogen systems. When making this decision, factors such as frequency of use, required insulation performance, and operational flexibility should be considered.

We are committed to providing you with the vacuum insulation system that best meets your needs. Choose the ideal vacuum insulation solution for your liquid nitrogen system. If you have any needs, please do not hesitate to contact us for further information or assistance.

To gain a deeper understanding of the difference between dynamic and static vacuum insulation, please click on the following blog link:

Dynamic Vacuum Vs Static Vacuum (csm-cryogenic.com).

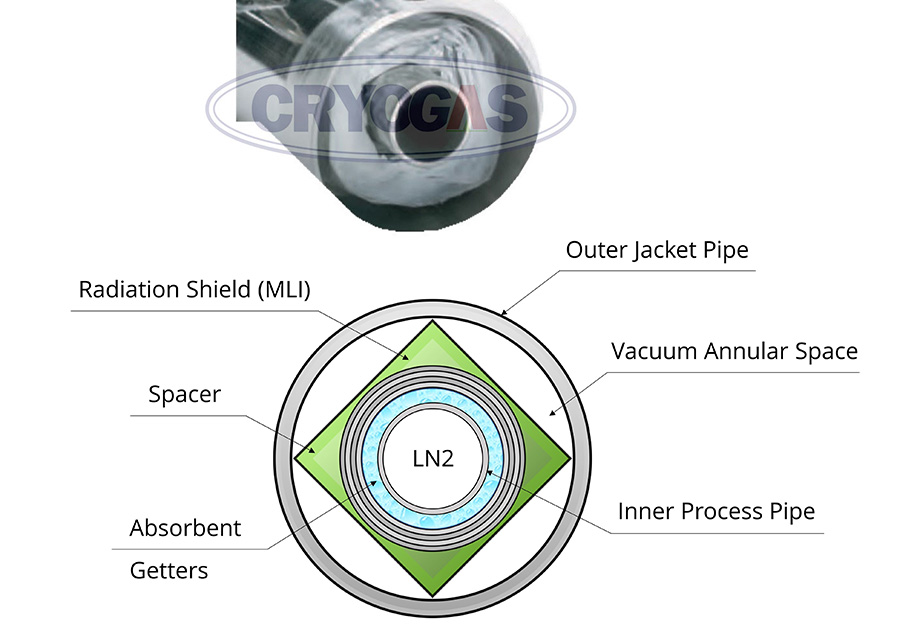

Typical structure of static vacuum

The success of super insulation depends on the following parameters:

- The gas release rate of materials used in vacuum annular spaces, such as partitions and radiation shielding materials

- The absorption rate of adsorbents and adsorbent materials, as well as their ability to remove various gas molecular species that form a vacuum ring for a long time, in order to extend the integrity of the vacuum

- Package design and technology to avoid linear thermal conduction of radiation shielding itself, which can lead to increased heat leakage

- The stacking degree of radiation shielding and gaskets is crucial to ensure that solid conduction is kept to a minimum, and an increase in volume and density will increase the solid thermal conduction between MLI layers