CRYOGAS adopts a specially designed radiation shield with an extremely low emission coefficient (ε), indicating its outstanding ability to minimize thermal radiation. This radiation shielding is manufactured to be only a few micrometers thick, greatly reducing the absorption of radiant heat (Qr) into low-temperature systems.

When the radiation shielding layer effectively reflects a portion of the radiant heat, it also absorbs and transfers some of the heat to adjacent layers through solid conduction. To alleviate the radial heat transfer between these adjacent radiation shielding layers, we used spacers. These gaskets are made of our proprietary inorganic glass fiber material, which is both flame-retardant and compatible with liquid oxygen, certified to comply with the US DOT MC-338 standard. The spacer has a specific porosity and can form an effective thermal barrier in the form of a gap vacuum space.

To ensure the highest quality and performance of our super insulating materials, we have carried out meticulous degassing treatment on them. The process involves placing the material under extreme high temperature and ultra-high vacuum conditions, combined with a low-temperature condensation procedure. Through this program, volatile hydrocarbons, water vapor, and lighter gas molecules are effectively removed.

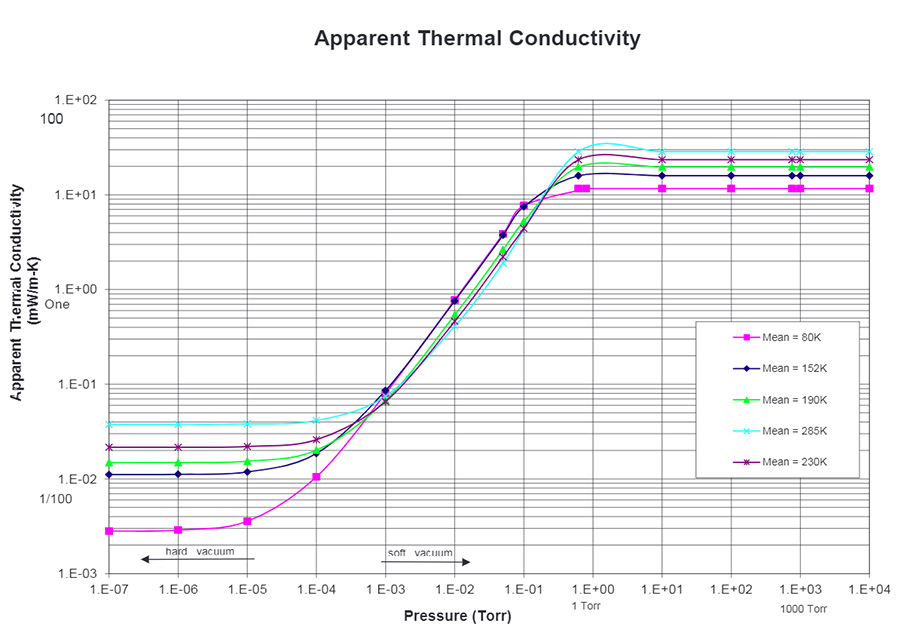

Then, using a semi-automatic winding machine, the double-layer super insulation material is skillfully applied to the process pipeline to form multiple layers of insulation. Careful control of the winding load ensures a consistent packing density of 25 layers per centimeter throughout the entire length of the pipeline. In order to achieve the ideal radiation thermal barrier, we carefully applied over 40 layers of radiation shielding based on our computational model. After this application, the product undergoes high-temperature baking and ultra-high vacuum evacuation processes to eliminate any residual moisture and gas molecules in the annular space. Eventually, a product with extremely low apparent thermal conductivity (Kt) was formed, with almost no heat leakage, thus preventing the evaporation of expensive refrigerants.

In order to ensure accurate heat leakage calculations in the design process of low-temperature systems, manufacturers conduct tests to ensure the apparent thermal conductivity values of multi-layer insulation materials (MLI) and provide these crucial data.

By conducting these tests, manufacturers can obtain accurate measurements of MLI thermal conductivity, which is crucial for accurately calculating heat leakage. These pieces of information play a crucial role in designing low-temperature systems that can effectively reduce heat transfer and maintain the desired temperature range.

Therefore, it is crucial for manufacturers to prioritize these tests and share the resulting data. By doing so, engineers and designers can make informed decisions when choosing the appropriate MLI and optimizing the thermal performance of the system.

In summary, the manufacturer promises to conduct testing and provide accurate data on MLI apparent thermal conductivity, which is an important step in ensuring efficient and reliable operation of low-temperature systems. CRYOGAS can provide a white paper on our product's thermal leakage and how it compares to competing product technologies in the market.

The main advantages of multi-layer super insulation are:

- Reduce the evaporation of refrigerant

- Eliminate gas-liquid interaction in pipelines

- Provide stable freezing pressure and temperature for your equipment

- Faster investment return

At CRYOGAS, we are committed to using advanced manufacturing technologies and processes to provide high-quality products that meet the strict requirements of low-temperature applications. By adopting our state-of-the-art insulation solutions, you can achieve optimal thermal efficiency and minimize wasted heat losses in low-temperature systems.